High-Performance Thermosetting Resin for carbon composites

CBZ contributes to optimizing CFRP component manufacturing by achieving

lightweight design and cost reduction through outstanding "productivity" and "CFRP properties.

What is CBZ?

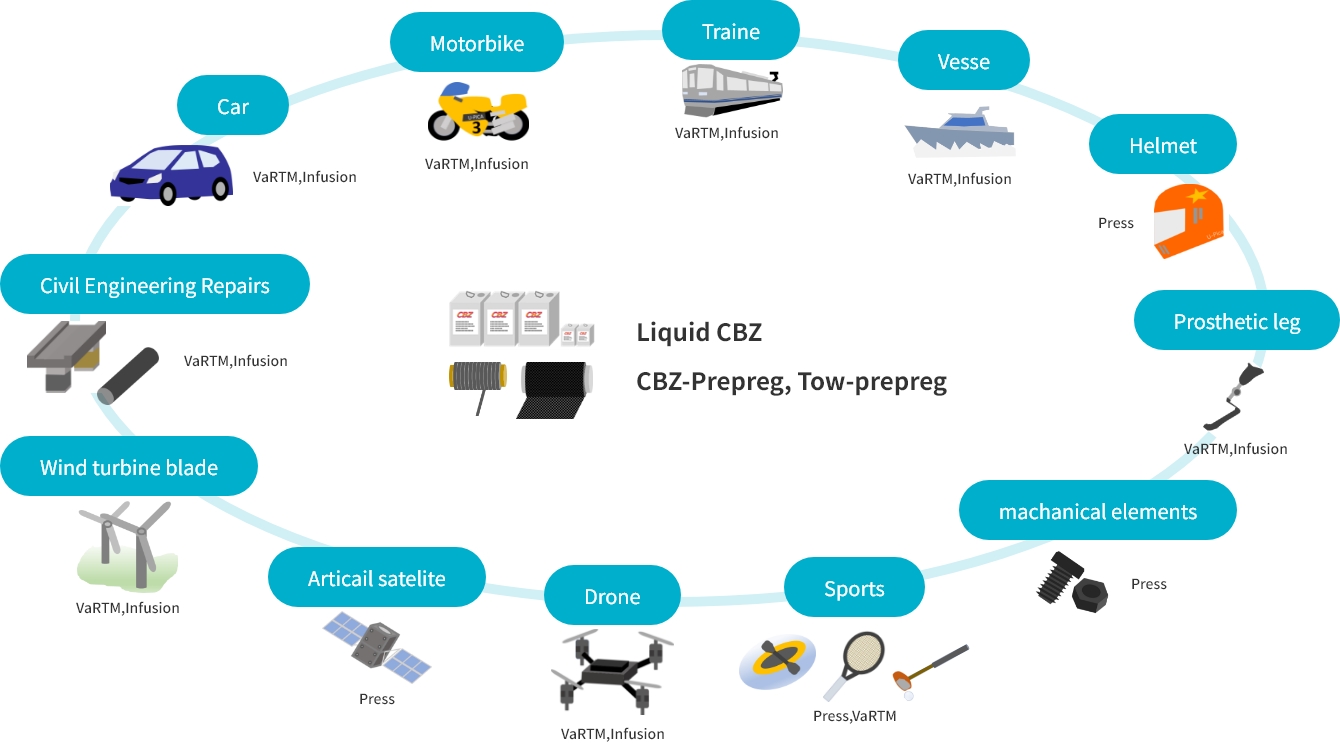

CBZ is a thermosetting resin developed for carbon fiber reinforced plastics (CFRP). It is also a resin that can contribute to customers in terms of manufacturing costs. We have a lineup of liquid resins and intermediate materials, which are used in a wide range of fields.

View larger

View larger

Customer Comments

Customer A

Molding : Pultrusion

[Product : CBZ 500MH-AS]

It can be produced at three times the production speed of epoxy resin, leading to a significant improvement in productivity.

Composite mechanical properties are also excellent.

Customer B

Molding : Press, Autoclave

[Product : CBZ prepreg]

With a short curing time, it achieved composite mechanical properties equal to or greater than those of conventional products.

Customer C

Molding : VaRTM.

Infusion

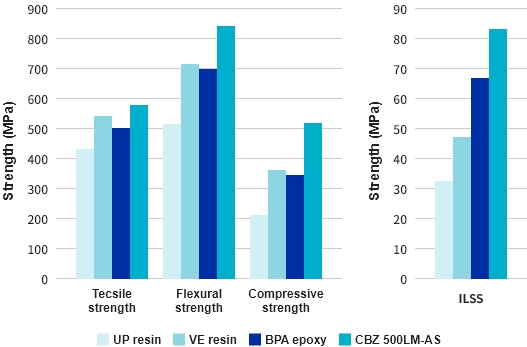

[Product : CBZ 500LM-AS]

Due to its high composite mechanical properties, the number of carbon fiber layers can be reduced, resulting in weight reduction and cost savings.

Customer D

Molding : Press, Autoclave

[Product : CBZ prepreg]

With fewer pinholes on the surface of molded products, the painting process was reduced from five to three steps, resulting in a significant improvement in productivity.

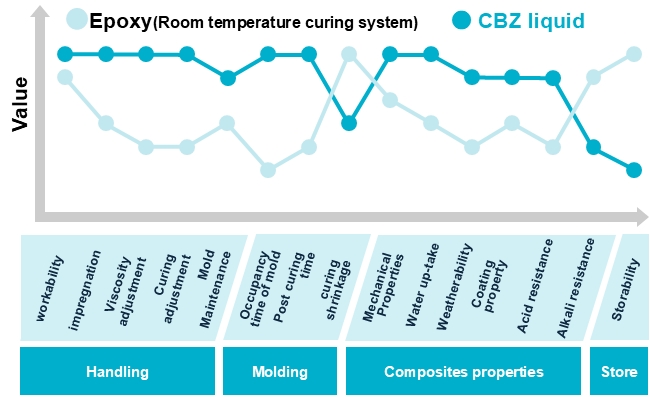

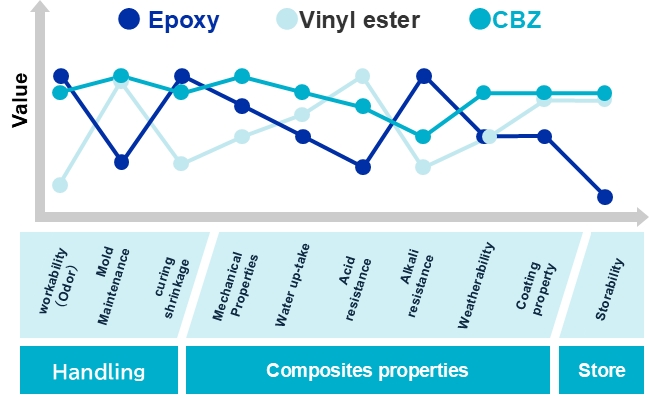

Value

Liquid CBZ

CBZ intermediate

Value for customers

1.Cutting manufacturing costs

point

01

High productivity

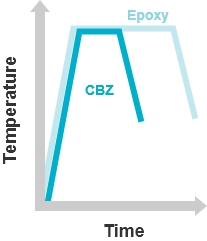

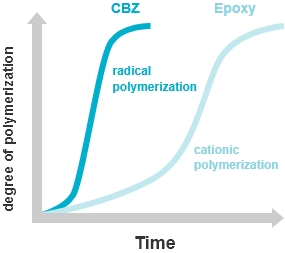

Shorter Curing Time: CBZ is a radical polymerization resin, meaning it cures faster than epoxy-based materials, significantly improving productivity and reducing labor costs.

e.g.1Pultrusion molding cost

The pultrusion speed can be 2.5 to 3 times faster than that of epoxy.

e.g.2Autoclave molding cost

Using CBZ prepreg, as compared to epoxy prepreg, significantly lowers overall costs by reducing labor, coating, and utility expenses.

point

02

Reduction in material usage

CBZ-CFRP delivers significantly higher performance compared to other radical polymerization resins, particularly excelling in flexural properties and interlaminar shear strength.

point

03

Reduction in the painting process (CBZ prepreg)

Excellent surface finish

2.Provision of high-strength and high-reliability components

Maintains mechanical properties under various conditions.

point

01

Fatigue resistance

point

02

Heat exposure resistance

point

03

Weathering resistance

(Sunshine carbon arc test)

point

04

Retention rate of physical properties

after water absorption 【14days at 70℃】

3.Commitment to environmental sustainability

Comparison of annual electricity consumption

40% reduction in electricity consumption

It also contributes to the reduction of CO2 emissions.

CBZ lineup