Thermosetting dry molding compound

VYLOGLASS

A thermosetting dry molding compound suitable for applications requiring heat resistance and high reliability, such as electrical components, electronic components, and automotive electrical components.

VYLOGLASS

VYLOGLASS is a dry molding compound containing a crystalline radical polymerization type thermosetting resin developed exclusively by our company. It is an environmentally friendly next-generation material that provides the heat resistance and high reliability required for electrical components, electronic components, and automotive electrical components, while also contributing to efforts to realize a sustainable society.

Battery holder

Battery cell holder

Quick charger

Terminal block

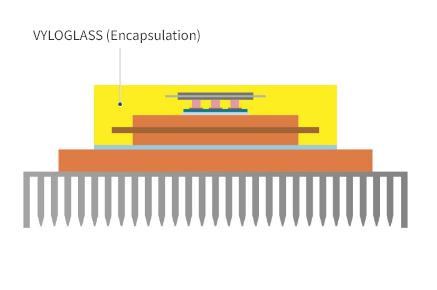

Encapsulation for ECU

Encapsulation for power modules

Customer’s Benefits

1.Contribution to sustainability

VYLOGLASS reduces energy consumption throughout the entire production process, minimizing the environmental burden.

Estimated material usage:10 tons per month

Estimated power consumption

Injection molding machine:1.6 kW

Curing oven:70 kW

Cold storage warehouse (-25 ℃) :68 kW

Electricity rate

$0.13/kWh (USD/JPY=150)

CO₂ Emission Factor

0.459 kg-CO₂/kWh

point

01

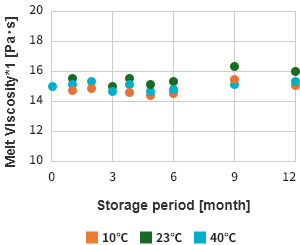

No need for frozen storage

Epoxy molding compounds require frozen storage, but VYLOGLASS can be stored at room temperature for one year.

This eliminates the need for refrigerated storage and reduces the energy required for refrigeration, thereby reducing CO2 emissions.

point

02

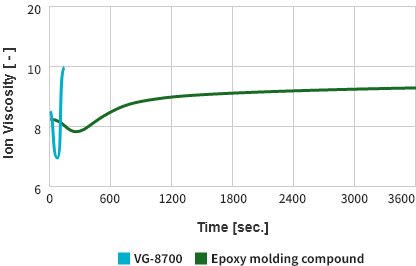

No post-cure required

VYLOGLASS does not require additional heat treatment (post-cure) after hardening.

This will shorten the manufacturing process and reduce thermal energy consumption, thereby reducing CO2 emissions.

2.Improved product safety

VYLOGLASS has excellent heat resistance, flame retardancy and electrical properties, providing the high level of safety required for electrical components, electronic components and automotive electrical components.

point

01

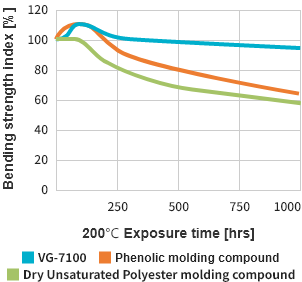

Long-term heat resistance

Maintains high strength even after heating test at 200℃ for 1,000 hours

※VG-7100 (RTI:180℃)and VG-7150 (RTI:130℃) are UL746B registered.

Halogen and heavy metal free.

※VG-7100 and VG-7150 are UL94 V-0 (0.8 mmt) certified.

point

03

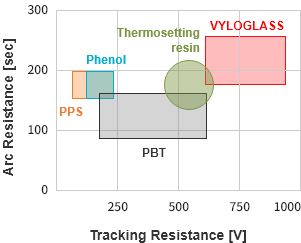

Electrical characteristics

- Tracking resistance of 600 V or more (PLC 0)

- Arc resistance of 180 seconds or more (PLC 4)

Product overview (including products under development)

Our lineup of thermosetting dry molding compound “VYLOGLASS”, includes the "UP Series," which blends unsaturated polyester resin into the matrix resin, and the "UA Series," which blends urethane acrylate resin.

UP series (UL certified)

Molding compound for safety parts with excellent long-term heat resistance and flame retardancy

UA series

Encapsulation molding compound based on Urethane Acrylate (UA) resin with excellent fluidity

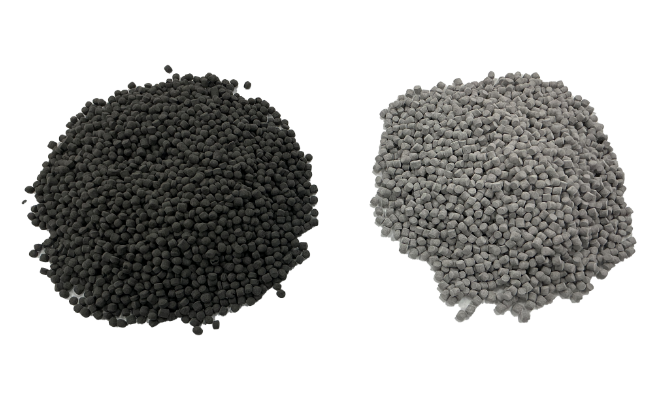

Shape/Color

UP series

Pellet (black/gray)

UA series

Granule/Tablet (black)

Molding method

Injection molding

Transfer molding

Compression molding

(UP series)

Product number